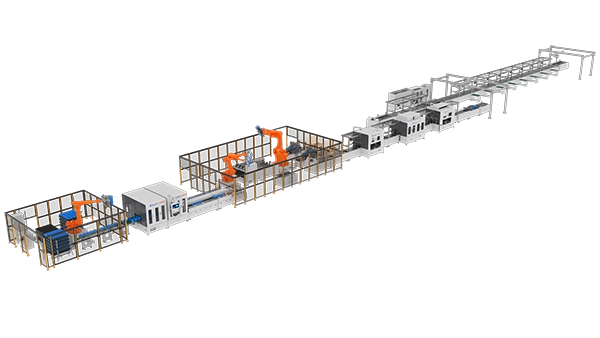

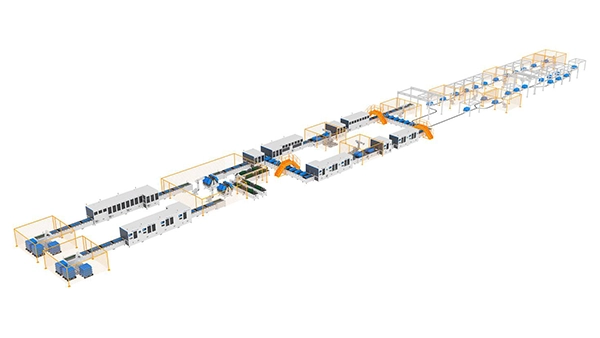

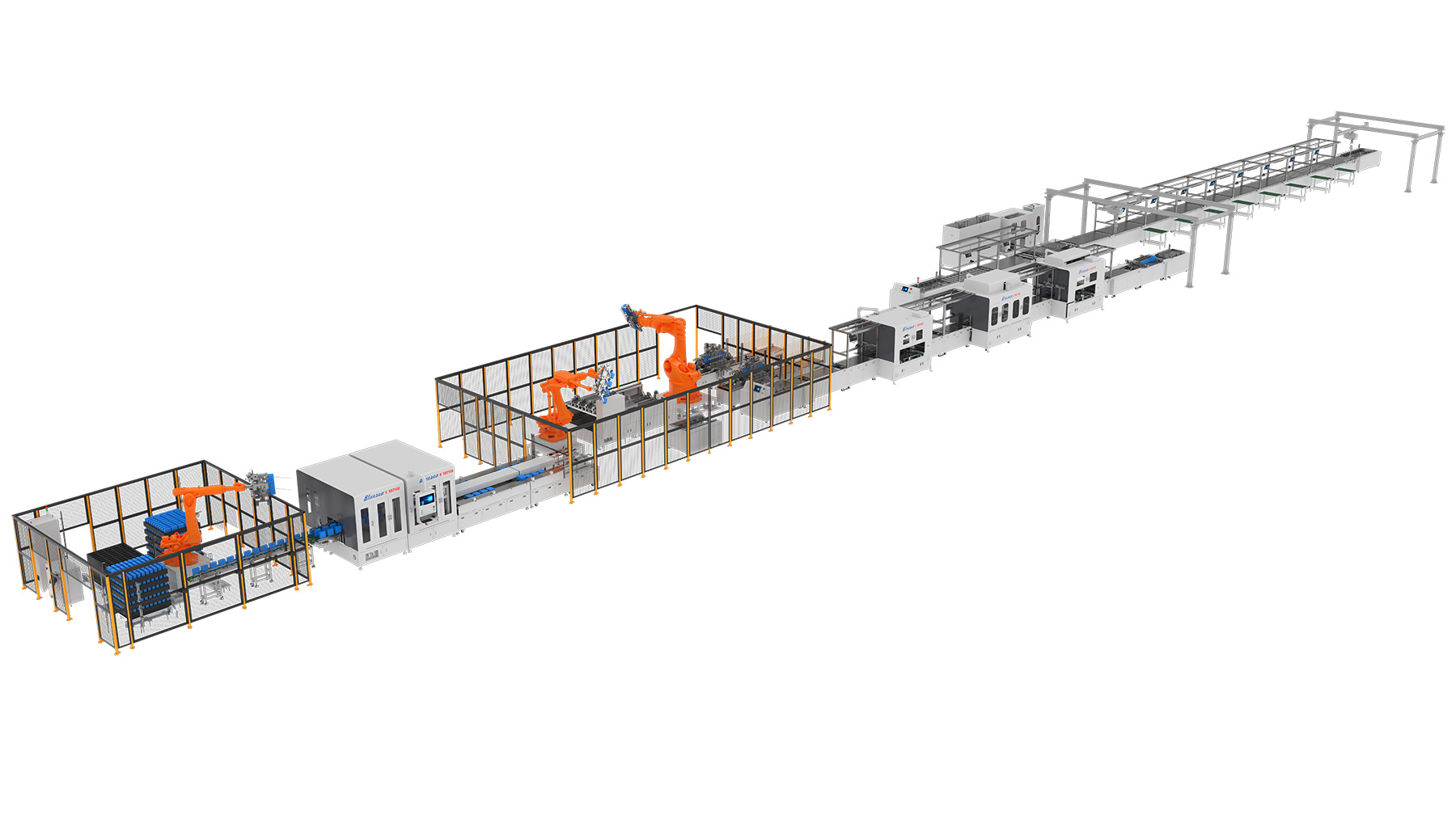

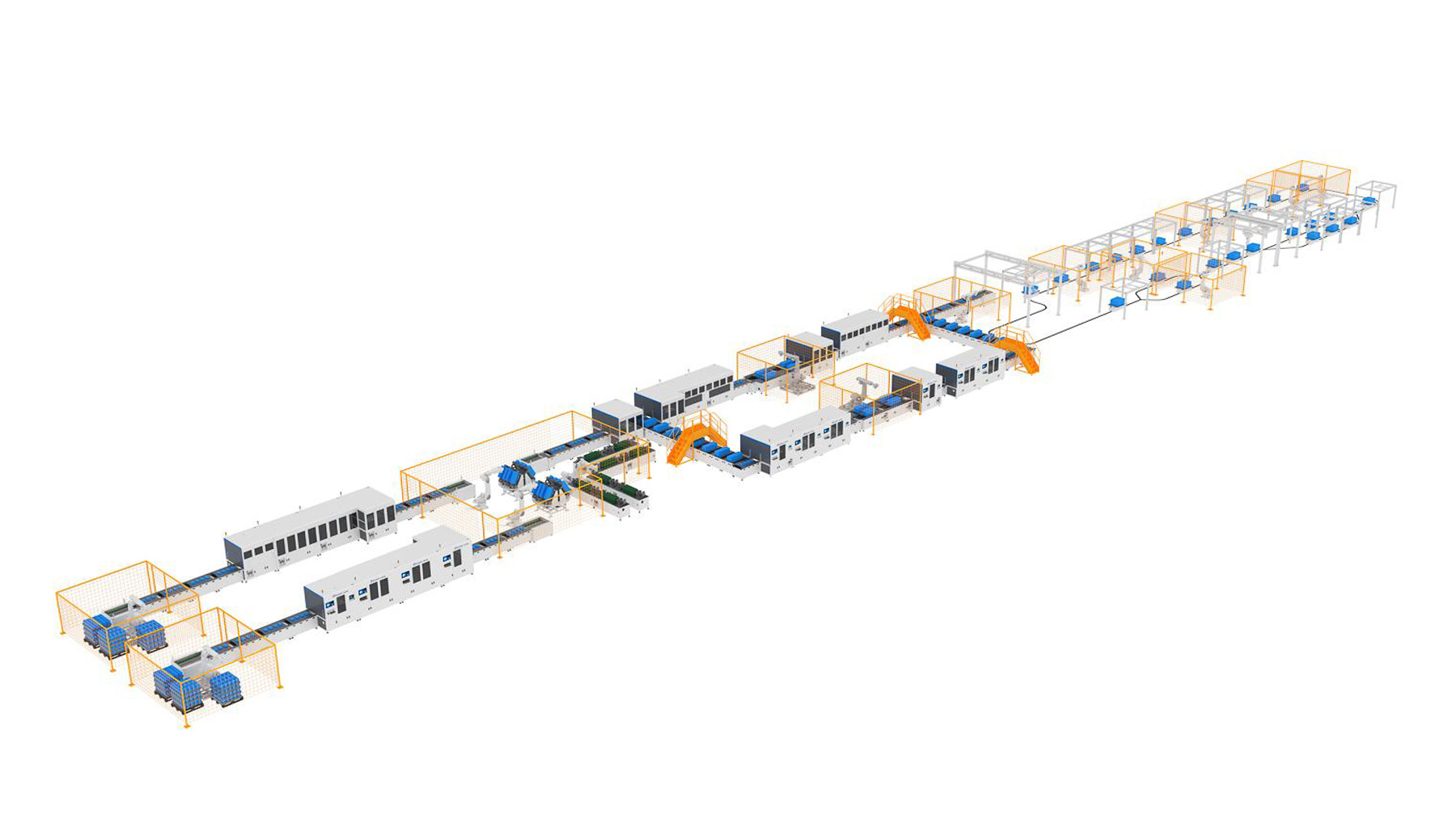

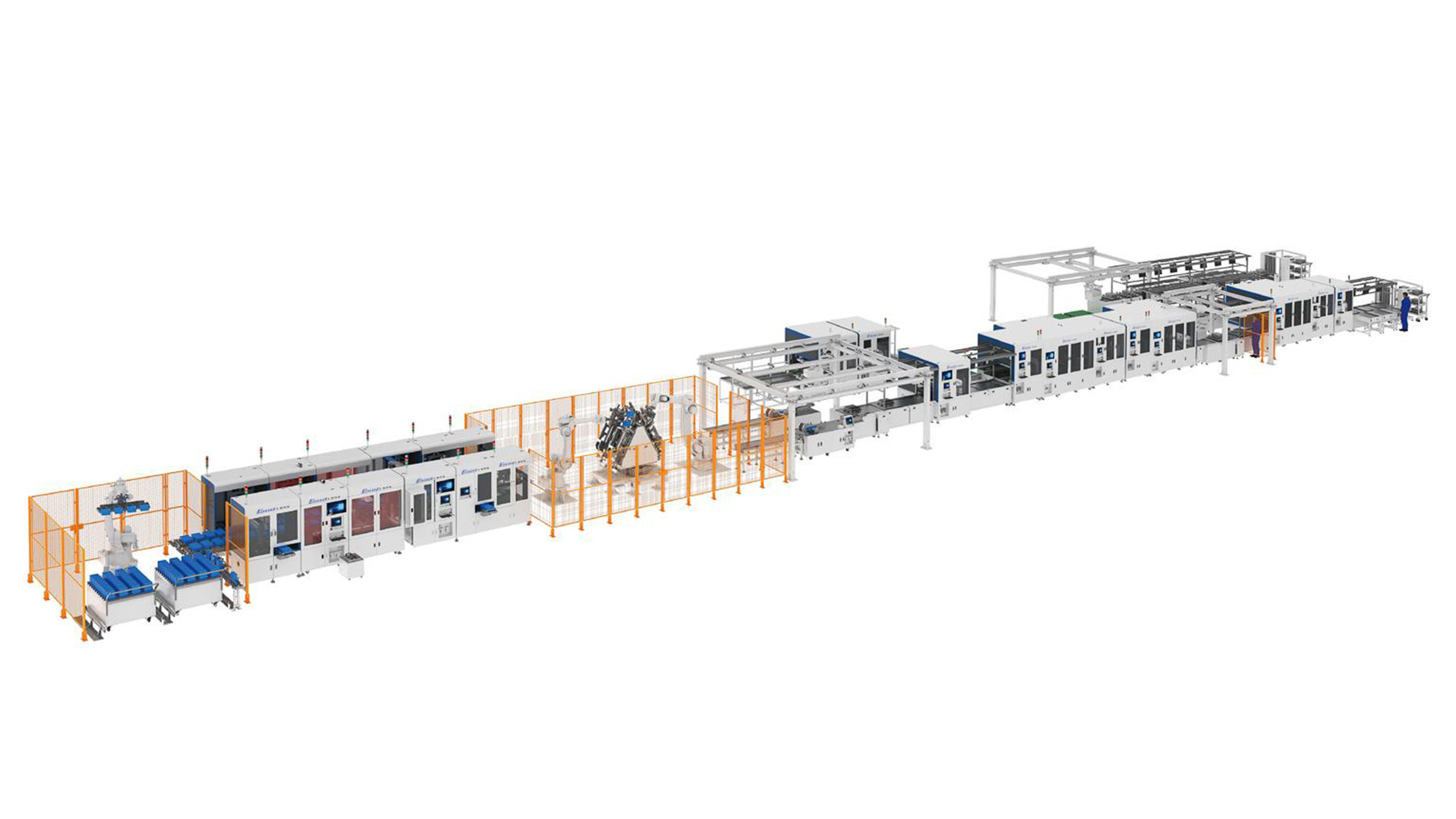

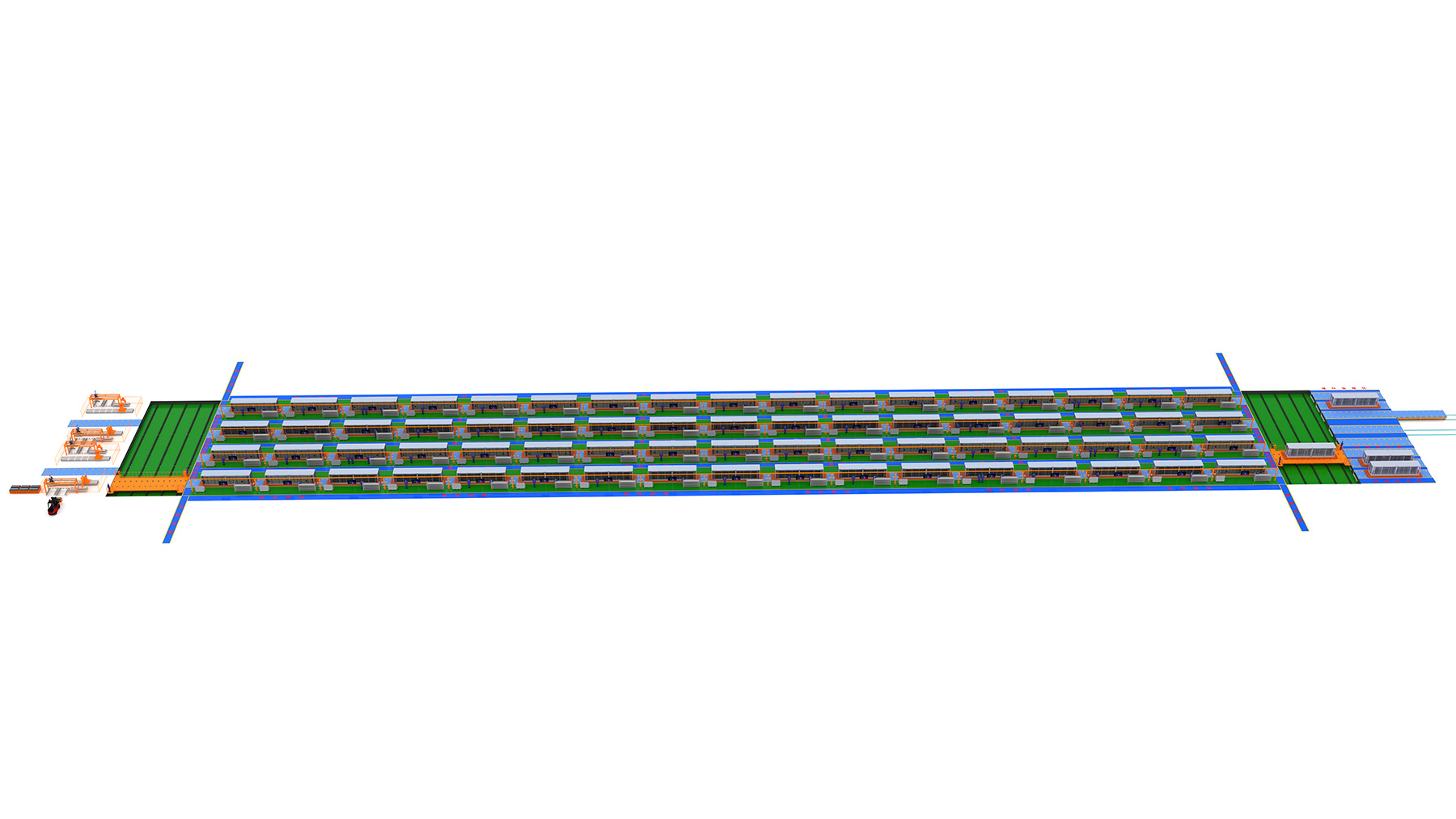

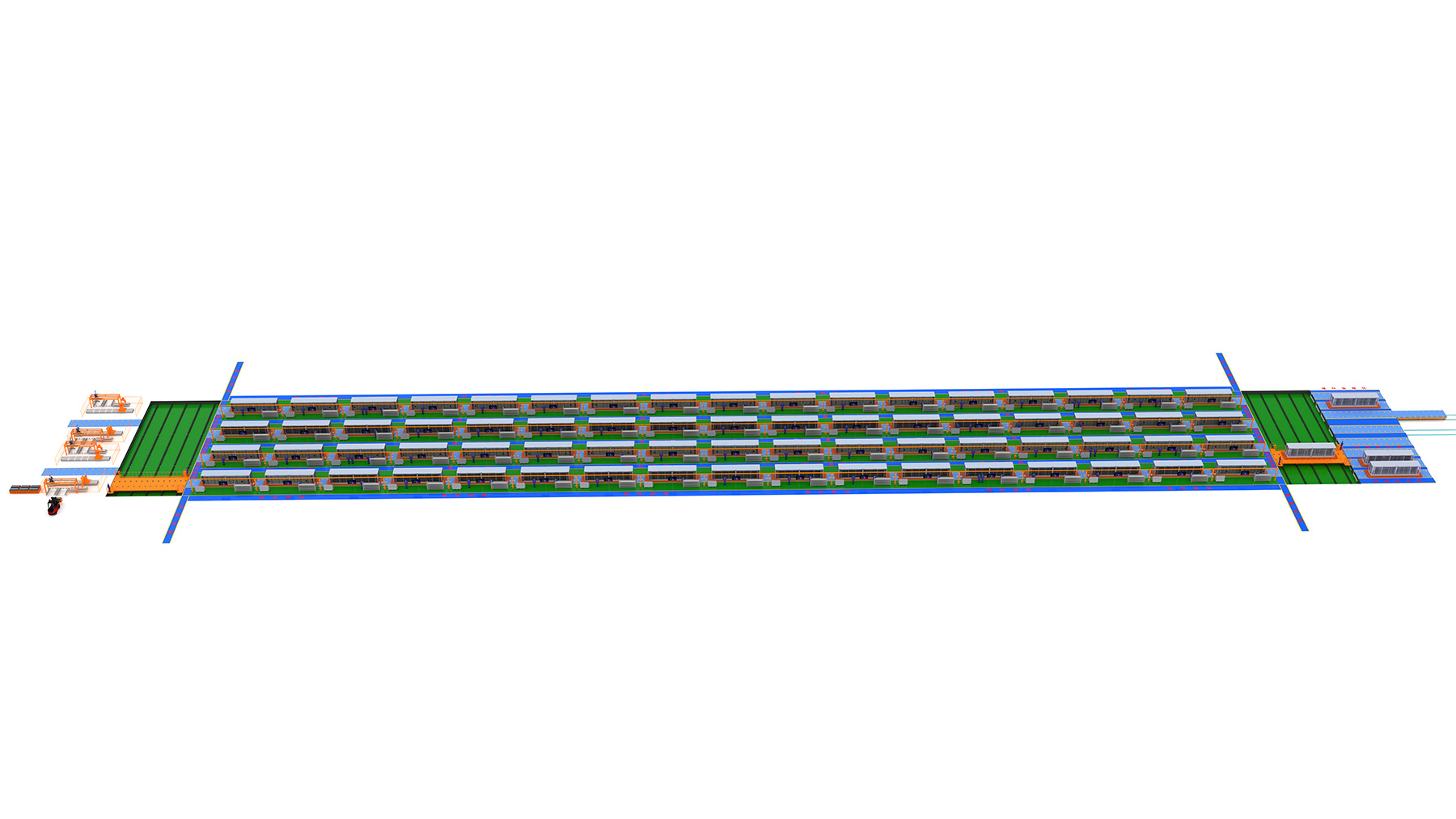

Automated Production Line For Energy Storage Containers

- Product Detail

-

Product Strength

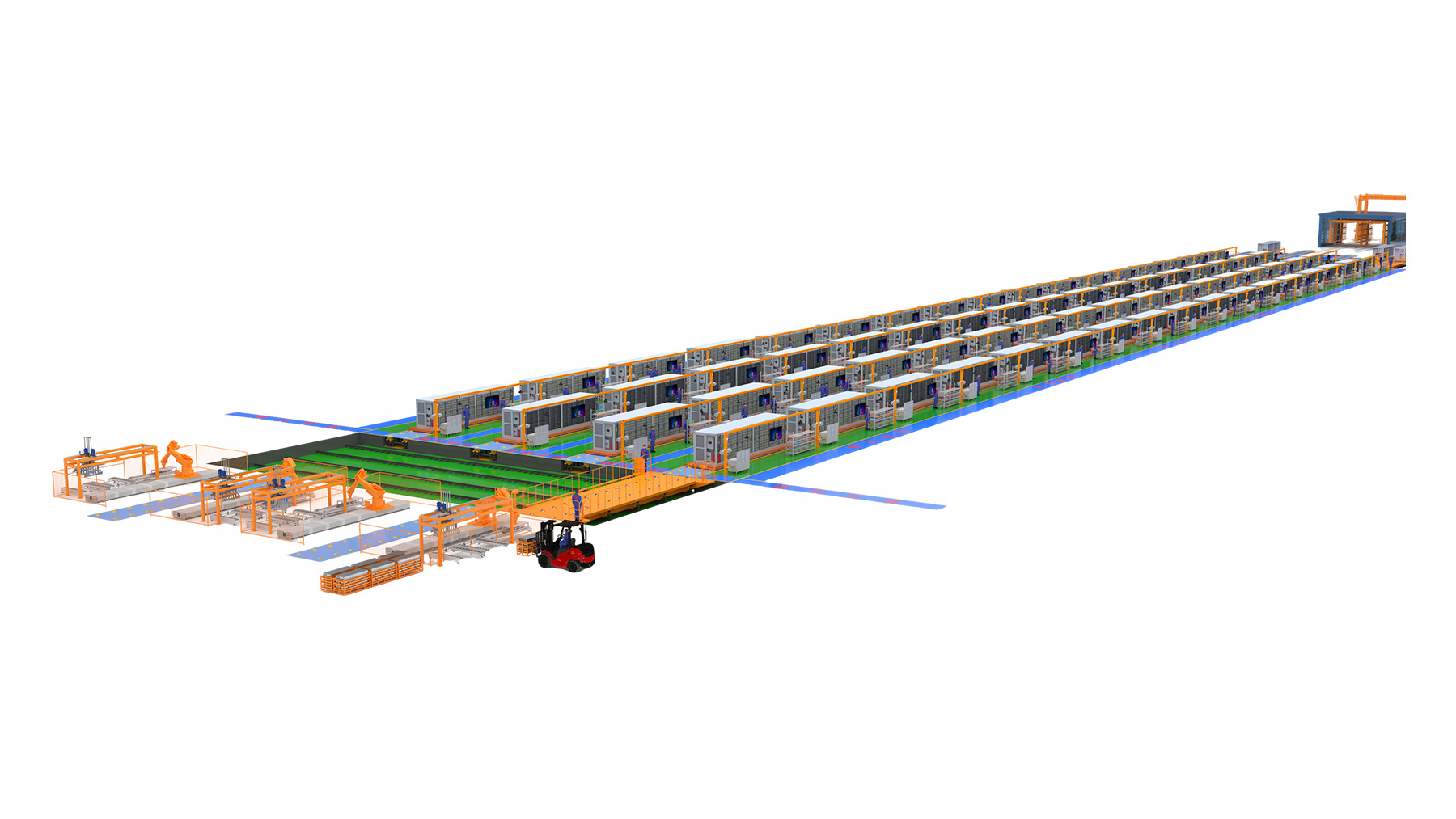

The production capacity is 10 container cabinets per shift, adopting an automatic clustering solution, which significantly enhances operational safety, reduces labor intensity, and improves production efficiency.The height difference between the busbars of each roller bed is ≤±0.5mm, and the repeat positioning accuracy of the sled is ≤ 10mm.The container has a self-locking function when reaching the designated position, with position signals electrically linked to the PACK loading control system.

The logistics channel s made of 10mm steel plates,allowing passage for 5T forklifts.

A modular layout is adopted,with equipment installed level with the ground,reducing operation height and work difficulty.This significant- ly enhances safety and work efficiency while increasing equipment stability and reliability.The overallequipmentlifespan is no less than 10 years.

Each section of the roller bed is equipped with sensors before and after the card reader for speed and position detection and control.Abutton operation box is provided, including functions such as manual/automatic switching, reset, emergency stop, completion,forward, and backward. The maximum load capacity of a single roller bed is 80T, compatible with the production of 20-40ft energy storage containers.

A hydraulic lifting function is adopted, with a lifting capacity of no less than 80T and a height of no less than 3Omm, meeting the high-voltage testing requirements for energy storage cabinets.

Use for

Applicable to 20-40 Foot Energy Storage Cabinet Container Automated Production Line

Manufacturer supporting the autonomous R&D of the enfire module PACK automafion production line

MES R&D Team

Workshop and factory wide MES saltaredevelopment

Sheet Metal and Logistics Team

In house sheet meal faclory and bogisics line R&D and design

Container Team

R&D offuly aulomaled conlainer assembty line

Laser Applicafon Team

R&D of laser vision, applcalon contrdl, welding lechndlogy

Robot Application Team

Full-line robot applicatian development, debugging, operalion & maintenance

Vision Application Team

Fulline vision apolcation and inegration R&D

Qualification Honor

Product Inquiry

Related Products